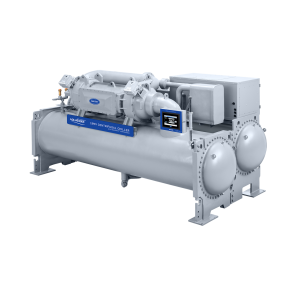

19XR/XRV AquaEdge® - Single-stage centrifugal liquid chiller

Compressor: centrifugal

Nominal cooling capacity: 300 to 3000 Tons (1055 to 10551 kW)

The Carrier

19XR/19XRV centrifugal chillers provide exceptional value by achieving energy

efficiency levels as high as 6.8 (COPr) utilizing proven technology designed

specifically for chlorine-free refrigerants.

- Single-stage compressor

- Industry-leading Efficiency with VFD

- Standard or high-tier VFD on choice

- Wide Application

- Stable Operation

- Low Sound Level

- Modular Construction

- Nominal cooling capacities from 1,000 to 5,300 kW

- Mix-match capabilities - a complete line of compressors and heat exchangers to ensure the optimal combination of machine components regardless of capacity, lift and efficiency specifications

- Hermetic compressor - elimination of leak risks from the compressor/motor shaft sealing in an open compressor

- Single-stage compressor with special features-aerodynamically contoured impellers, variable inlet guide vanes and movable diffusers for better compressor part and full-load operating efficiency

- Variable speed compressor capability - improvement of part load efficiency and electrical performance

- Heat exchangers certified by the European pressure vessels code (PED), and all marine code certifications

- Interface Chiller Visual Control (ICVC) - a large LCD (liquid crystal display) features 4 menu-specific soft keys. The default display offers all in one glance review of key chiller operation data, simplifying the interaction between chiller and user

- Two types of unit-mounted variable frequency drives (VFDs)

- Refrigerant isolation valves allow the refrigerant to be stored inside the chiller during service

- Hot gas by-pass for surge prevention during operation at high condensing temperature or for optimized operation at low load conditions

- Spring isolators adapted for all chiller configurations

- Unit-mounted starter reduces machine installation time and expense

- High voltage motors available

- CCN/JBus or CCN/BACnet: remote connection

- 21 bar water heat exchanger

- Waterbox with flanges and counter-flanges

- Delivered in multiple sections to facilitate the installation

- Refrigerant leak detector module: unit mounted sensor (not compatible with 19XRV VFD)

- Catalogue 19XR - Specifications Published Date: 20/01/2022

Touch Pilot control system

- Strong control and monitoring function during chiller operation

- 10.5" high resolution touch screen

- Can support more than 10 languages

- Real time display of operation parameters

- Nominal cooling capacities from 1,000 to 5,300 kW

- Mix-match capabilities - a complete line of compressors and heat exchangers to ensure the optimal combination of machine components regardless of capacity, lift and efficiency specifications

- Hermetic compressor - elimination of leak risks from the compressor/motor shaft sealing in an open compressor

- Single-stage compressor with special features-aerodynamically contoured impellers, variable inlet guide vanes and movable diffusers for better compressor part and full-load operating efficiency

- Variable speed compressor capability - improvement of part load efficiency and electrical performance

- Heat exchangers certified by the European pressure vessels code (PED), and all marine code certifications

- Interface Chiller Visual Control (ICVC) - a large LCD (liquid crystal display) features 4 menu-specific soft keys. The default display offers all in one glance review of key chiller operation data, simplifying the interaction between chiller and user

- Two types of unit-mounted variable frequency drives (VFDs)

- Refrigerant isolation valves allow the refrigerant to be stored inside the chiller during service

- Hot gas by-pass for surge prevention during operation at high condensing temperature or for optimized operation at low load conditions

- Spring isolators adapted for all chiller configurations

- Unit-mounted starter reduces machine installation time and expense

- High voltage motors available

- CCN/JBus or CCN/BACnet: remote connection

- 21 bar water heat exchanger

- Waterbox with flanges and counter-flanges

- Delivered in multiple sections to facilitate the installation

- Refrigerant leak detector module: unit mounted sensor (not compatible with 19XRV VFD)

- Catalogue 19XR - Specifications Published Date: 20/01/2022

to find out more, you can contact us at

Inquiry Form Call Center: (+62) 21 2660 8088 Chat with us on Whatsapp